Categories

- Stainless Steel Tubing Coil (20)

- Seamless Stainless Steel Tubing (42)

- Stainless Steel Welded Pipe (13)

- Stainless Steel Pipe Fittings (25)

- Duplex Stainless Steel Pipe (7)

- Sanitary Stainless Steel Pipe (10)

- Forged Socket Pipe Fittings (6)

- Stainless Steel Flanges (12)

- Nickel Alloy Steel Pipe (19)

- Forged Thread Pipe Fittings (11)

- Stainless Steel Olets (3)

Stainless steel seamless pipe manufacturing process

Stainless steel seamless pipe is a kind of long strip steel with hollow section and no seam around.The thicker the wall of this product, the more economic and practical it will be. The thinner the wall, the higher its processing cost will be.

- Product Details

Stainless steel seamless pipe

Stainless steel seamless pipe is a kind of long strip steel with hollow section and no seam around.The thicker the wall of this product, the more economic and practical it will be. The thinner the wall, the higher its processing cost will be.

Decide the limits of its performance of the product process, generally low precision seamless stainless steel pipe: low surface brightness, uneven thickness, tube length cost is high, and the appearance is not easy to remove and pitting, black spots inside;Its detection and shaping must be taken offline.Therefore, it shows its advantages in high pressure, high strength and material for mechanical structure.

Stainless steel seamless pipe manufacturing process

1. Hot extrusion (seamless steel tube) : the circular tube billet - heat - punch - three-roll skew rolling, rolling, or pressing - to take off the tube and sizing (or reducing) - cooling - straightening to hydrostatic test or inspection - > tag, put in storage

The raw material for rolling seamless pipe is round tube blank. The round tube blank will grow to about 1 meter after cutting and processing by cutting machine, and will be sent to the furnace through conveyor belt for heating.The billets are heated in a furnace at a temperature of about 1,200 degrees Celsius.The fuel is hydrogen or acetylene.The temperature control in the furnace is the key problem. After the round pipe billet is out of the oven, it should go through the pressure piercing machine.Generally, the more common piercer is the tapered roller piercer, which has high production efficiency, good product quality, large perforation diameter and can wear many kinds of steel.After perforation, the round pipe blank is rolled by three rolls of inclined rolling, continuous rolling or extrusion

After extrusion, take off the tube and set the diameter.The pipe is formed by the tapered drill rotating into the steel embryo hole at high speed.The inner diameter of steel pipe is determined by the external diameter length of the drill bit of the sizing machine.After the steel pipe is fixed in diameter, it will enter the cooling tower and be cooled by water spraying. After cooling, the steel pipe will be straightened.After straightening, the steel pipe is sent to the metal inspection machine (or water pressure test) by the conveyor belt for internal inspection.If there are cracks, bubbles and other problems in the steel tube, they will be detected.Steel pipe quality inspection after the strict manual selection.After the steel pipe quality inspection, paint the serial number, specification, production batch number and so on.The crane is hoisted into the warehouse.

2. Cold drawing (rolling) seamless steel pipe: the circular tube billet - heat - punch to heading, annealing and pickling to apply oil (copper), multi-channel time cold drawing (cold) and billet tube - heat treatment - straightening to hydrostatic test (NDT) - > tag, put in storage.

The rolling method of cold drawn (rolled) seamless steel pipe is more complicated than hot rolled (extruded) seamless steel tube.The first three steps of their production process are basically the same.The difference starts from the fourth step, after the round pipe blank is hollowed out, to hit the head, annealing.After annealing, use a special acid liquid for pickling.After pickling, apply oil.Then followed by a number of cold-drawn (cold rolled) rebillet tube, special heat treatment.After heat treatment, it will be straightened.

zheheng steel Chemical assurance

1.Each lot of raw materials will be tested by spectrometer before put in storage.

2.100%PMI the mother pipe to ensure we put right material.

2.100%PMI the finished pipe again to ensure we produced right grade

Heat Treatment Assurance

A full-automatic natural gas furnace with 24 meters in length.The real temperature tolerance could be within 10℃.

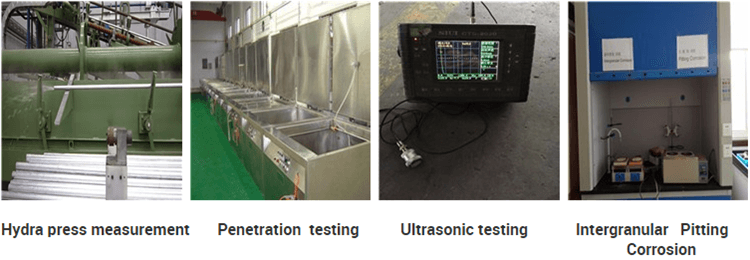

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking

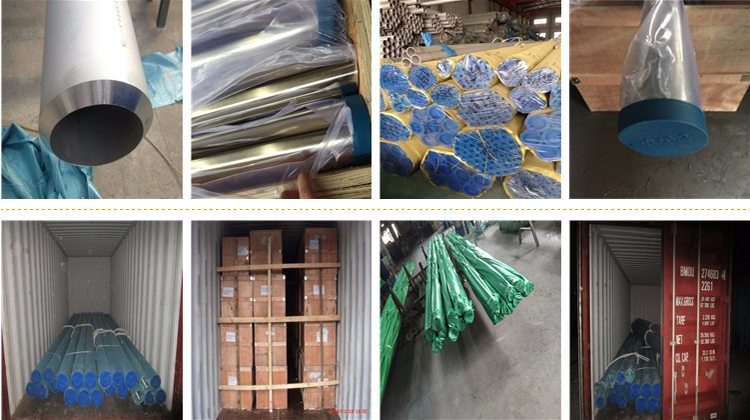

our product show:

our product show: