Categories

- Stainless Steel Tubing Coil (20)

- Seamless Stainless Steel Tubing (42)

- Stainless Steel Welded Pipe (13)

- Stainless Steel Pipe Fittings (25)

- Duplex Stainless Steel Pipe (7)

- Sanitary Stainless Steel Pipe (10)

- Forged Socket Pipe Fittings (6)

- Stainless Steel Flanges (12)

- Nickel Alloy Steel Pipe (19)

- Forged Thread Pipe Fittings (11)

- Stainless Steel Olets (3)

Inconel 625 pipe ASTM B444 / B704 /751 /705

Inconel625 is mainly strengthening elements molybdenum, niobium alloy solid solution strengthening type high temperature alloy, nickel base deformation with excellent corrosion resistance and oxidation resistance

- Product Details

Inconel 625 pipe is mainly strengthening elements molybdenum, niobium alloy solid solution strengthening type high temperature alloy, nickel base deformation with excellent corrosion resistance and oxidation resistance, from low temperature to 980 ℃ has good tensile performance and fatigue performance, and stress corrosion resistance to salt fog atmosphere.Therefore,

it can be widely used to manufacture aviation engine parts, aerospace structural parts and chemical equipment.The alloy used in the manufacture of engine casing, guide vane, installation components, such as edge and cylinder, fuel manifold has passed the assessment of practical application, the maximum temperature of 950 ℃.Alloy in 550 ~ 700 ℃ after long-term use of certain age hardening phenomenon, led to the decrease of the alloy plasticity has some.

|

Standard |

Inconel 600(UNS N06600/W.Nr.2.4816),Inconel 601,Inconel 625,Hastelloy C-276,GB/T 4435,ASTM B160 |

||

|

Density |

8.4 g/cm3 |

||

|

Melting point |

1370-1425℃ |

||

Inconel 625 Chemical Composition:

| % | Ni | Cr | Fe | Mo | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

| Min | 58 | 20 | 8.0 | 3.15 | |||||||||

| Max | 23 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.5 | 0.4 | 0.4 |

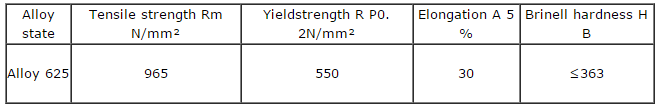

Minimum inconel 625 pipe mechanical properties in the room temperature:

product inconel alloy 625 pipe show: